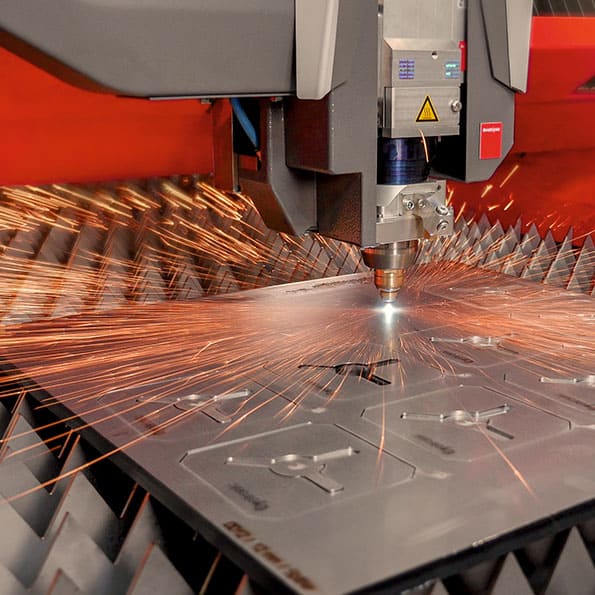

Laser Cutting

Service

We primarily use laser cutting as our main method for material processing, maximizing precision and minimizing material waste. Laser cutting not only allows for accurate cuts but also produces virtually burr-free edges, minimal deformation, and excellent cutting speeds, making it our preferred processing method. In the field of metal processing, we are committed to providing the highest quality and most reliable solutions to meet our customers' needs and expectations.

Advantages and Features

- We operate three Swiss Bystronic 15,000W flagship lasers, achieving cutting efficiency that exceeds three times that of conventional equipment.

- Coupled with advanced software, hardware, and automation solutions, we enhance equipment utilization rates and ensure reliable cutting quality.

- Our facility is equipped with 320 storage racks, allowing us to stock up to 1,600 tons of metal sheets at once.

- Our cutting capabilities extend to a width of 2,500 mm and a length of 8,000 mm.

Achievements

Our eight-meter laser cutting machine successfully produced aircraft and ship hull components in 2021, supplying precision sheet metal parts for Boeing and Airbus commercial aircraft, as well as domestic defense vessels in Taiwan.

Processing Capabilities

- Carbon Steel Thickness: 50mm

- Stainless Steel Thickness: 50mm

- Aluminum Alloy Thickness: 30mm

- Copper Alloy Thickness: 20mm

Applications

- Aerospace

- Machinery

- Automotive

- Engineering

- Heavy Electrical

- Shipbuilding

- Elevators

- Construction

- Food Industry

- Semiconductors