Design

Utilizing 2D and 3D software combined with over 20 years of design experience, we solve complex issues for our clients.

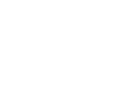

Raw Materials

We maintain a metal material reserve of up to 5,000 tons, with abundant inventory of black steel, stainless steel, galvanized steel, SECC, and aluminum alloy.

Shearing Machine

Using Japanese-imported 6-meter cutting equipment, we can precisely shear materials according to customer requirements, delivering accurate parts.

Grooving

Our imported, industry-rare 8-meter integrated grooving machine is equipped with Taiwan’s only rotating blade holder, achieving X and Y axis grooving capabilities.

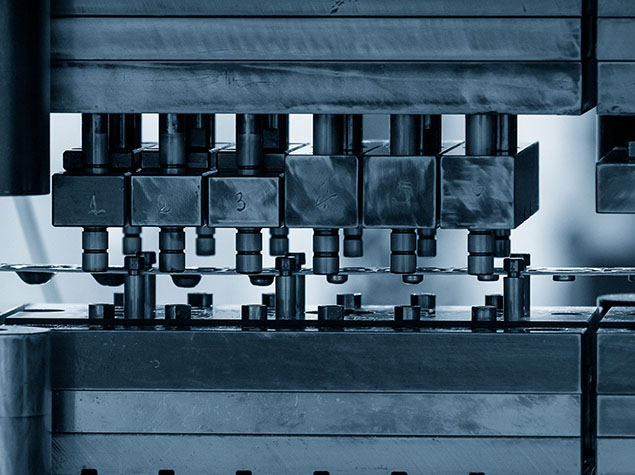

Stamping

Metal sheets are processed through a stamping press, forming the desired shape with the punch and die.

Bending

We are the only factory in Asia with an 8.6M German-imported synchronized bending machine, capable of bending workpieces up to 8.6 meters in a single process.

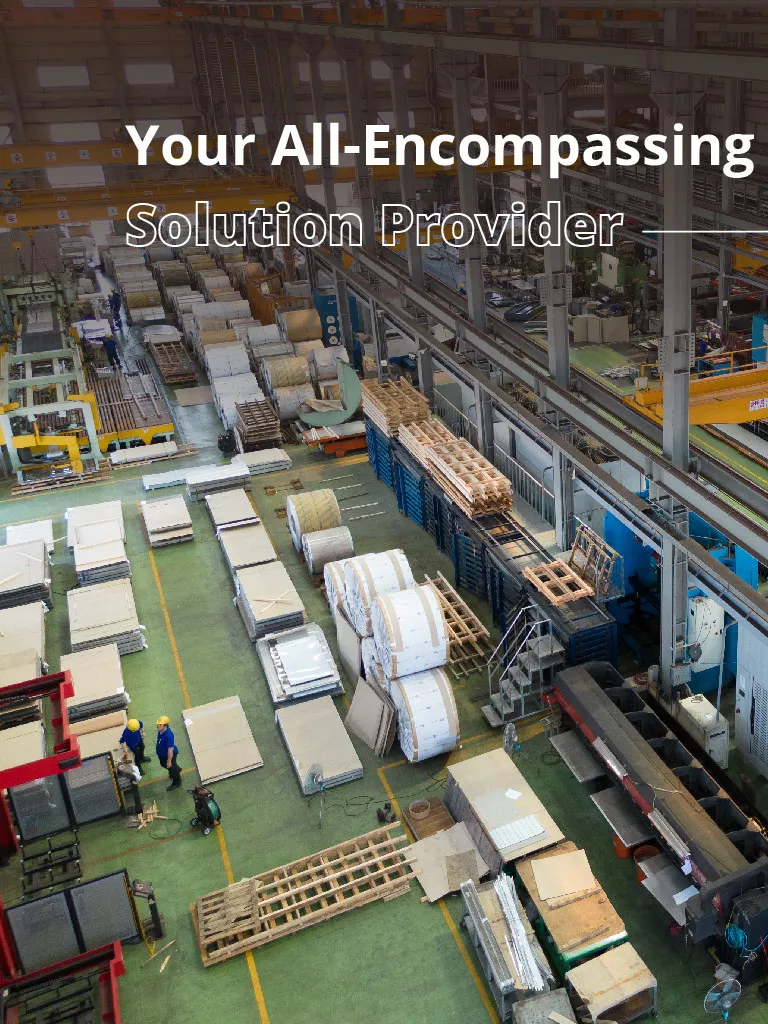

Laser Cutting

We operate three Swiss Bystronic 15,000W high-power flagship laser machines, with cutting efficiency more than three times that of standard equipment.

Rolling

The rolling process eliminates material stress, making the product's shape smoother and more aesthetically pleasing, enhancing the overall visual appeal.

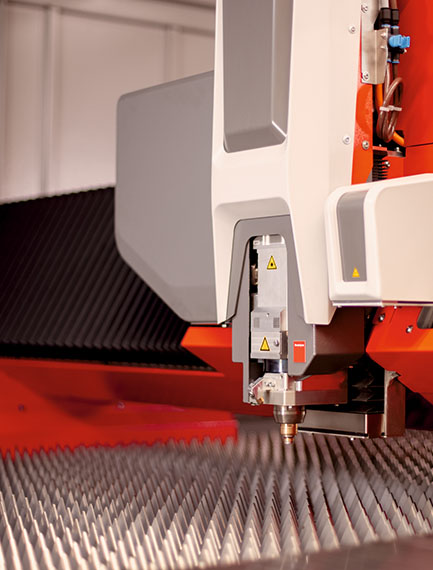

Assembly & Welding

Our professional welding team uses argon welding, CO2 welding, and fiber laser welding arms to complete assembly, significantly shortening the production cycle and increasing output speed.

Surface Processing

Our surface treatment allows for customized color, texture, and gloss, improving the visual effect and enhancing product competitiveness in the market.