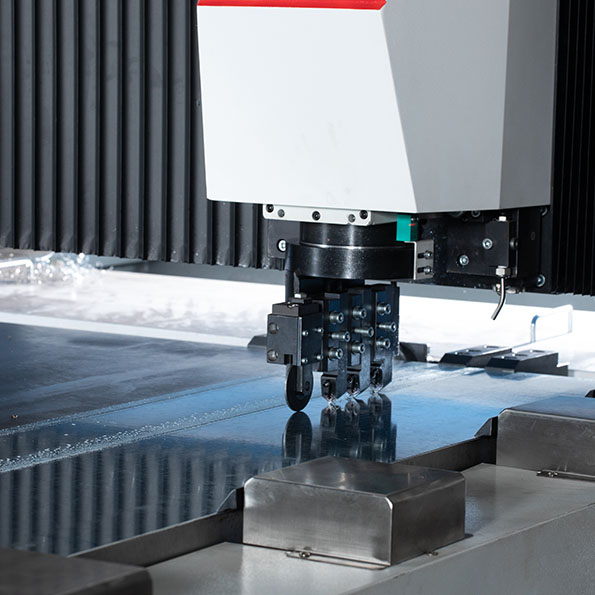

Grooving

Service

We can assist customers in processing metal raw materials into parts with grooves or embossed textures through our grooving operation, utilizing Japanese-made tools to achieve stable and precise grooving accuracy. Grooving can create grooves of controllable size and depth on the metal surface to meet specific bending requirements from our clients.

Advantages and Features

- We can provide a more diverse range of processing methods to meet different customer needs. Whether for producing curtain wall materials or mechanical components, grooving offers greater flexibility to satisfy client requirements.

- The grooving process enables precise size control and intricate bending shapes, which is especially important for industries requiring high-precision parts. As a result, we can deliver high-quality metal components through grooving, enhancing their competitiveness in the market.

- Compared to standard bending processes, grooved bending workpieces can achieve shapes and dimensions that typically require welding in traditional bending. By utilizing grooving, we can save welding time, complete customer orders more quickly, and deliver products in a shorter timeframe, thereby improving product competitiveness.

Achievements

Grooving is commonly used for aesthetically pleasing interior decoration components. Our company has long supplied major domestic interior design firms, the elevator industry, and high-end boutique display cases.

Processing Capabilities

- Black Iron: 8mm

- Stainless Steel: 8mm

- Aluminum: 8mm

- Brass: 8mm

- Copper: 8mm

- Length: 8M

Applications

- Machinery

- Engineering

- Construction

- Shipbuilding

- Elevators