Surface Processing

Service

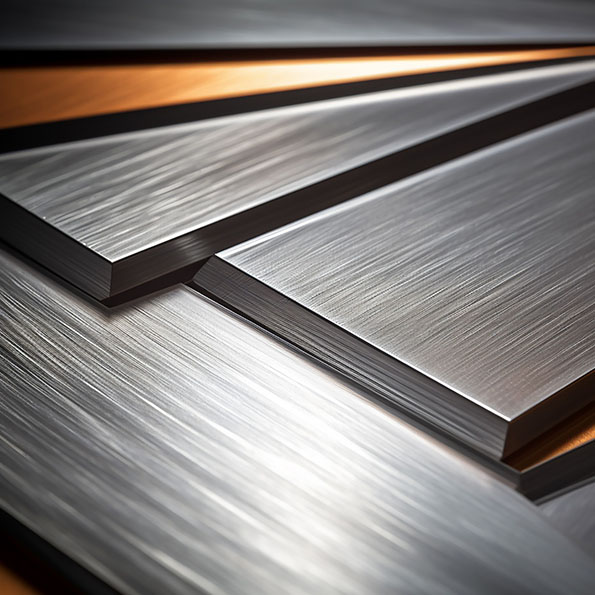

Various protective or decorative treatments are applied to the surface of metal products to enhance their appearance, durability, and corrosion resistance. Common surface treatment processes include painting, electroplating, and polishing, among others.

Advantages and Features

- Enhancing Product Appearance;Surface treatments allow for the customization of a product's color, texture, and gloss, improving overall visual appeal and increasing market competitiveness.

- Improving Corrosion Resistance; Surface treatments can create a protective layer on the metal surface, effectively resisting corrosion from environmental factors and extending the product's lifespan.

- Enhancing Durability;Surface treatments strengthen a product's hardness and wear resistance, significantly improving its ability to withstand wear and tear during use.

- Meeting Customization Needs;Our professional surface treatment team can provide a variety of processing options based on clients' personalized requirements, catering to different application scenarios.

Achievements

Our company has invested in a surface processing factory in Northern Taiwan, offering mirror, random pattern, and sandblasted finishes for stainless steel. We also have long-term partnerships with suppliers for other metal materials, along with dedicated quality assurance, allowing us to maintain control over the entire process from raw materials to finished products.

Processing Capabilities

- Titanium Plating

- Galvanizing

- Chromium Plating

- Powder Coating

- Anodizing

- Heat Treatment

Applications

- Aerospace

- Machinery

- Automotive

- Engineering

- Heavy Electrical

- Shipbuilding

- Elevators

- Construction

- Interior Design